JANTSA stands for quality in all products, services, processes, and culture.

Wheel is a safety component of the vehicle, which accepts no compromises on quality. Our OEM and aftermarket customers require the top quality of products. Therefore, we give utmost priority to the industry-leading methods of quality assurance and cutting-edge quality management system throughout the entire wheel production process.

Here, JANTSA benefits from its 40+ years commitment to wheel manufacturing and strong family business tradition. Our dedicated and highly skilled personnel stays at the core of our quality leadership. Each and every JANTSA employee feels a personal responsibility and honour for delivering superior products matching the strictest requirements of our worldwide customers.

JANTSA has implemented a quality management system that supports constant improvement of the entire organization. With this approach, we make sure that our worldwide customers benefit from the superior durability, reliability, and performance of our products and services.

SUPERIOR PRODUCT

With most of our products going to major OEMs worldwide, superior product quality is our key differentiator. Every manufacturing step at JANTSA assures the best quality and reliability of our products.

Raw Materials

Quality of raw materials has a major impact on safety of steel wheels. For every key component we cooperate with the globally leading suppliers, specialized in materials for wheel manufacturing. JANTSA continuously invests in skilled engineering personnel and sophisticated testing facilities. Thorough incoming control conducted in the world-class metallographic and mechanic laboratories assure the highest standard of steel, paint, welding wire, and semi-finished components used in our production.

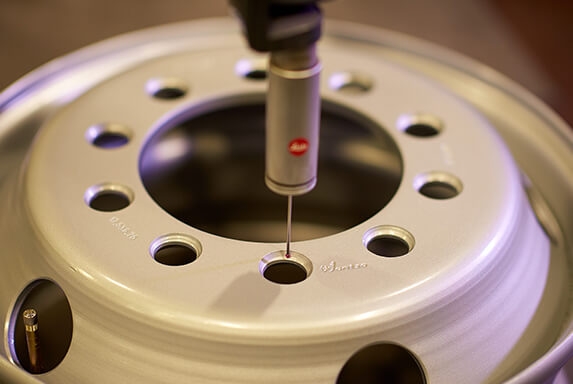

Product dimensions

Growing speed, vehicle weight, payload and horsepower of modern vehicles require precise wheel dimensions for maximum safety and driving comfort. Our wheels are inspected at every crucial step of production, including the 100% control for radial and lateral run-out. Right before the packaging, every wheel is visually examined and approved with JANTSA quality assurance seal. We also apply customer-specific measurement procedures, defined by requirements of our major clients.

Surface treatment

Superior wheel finish is crucial for rust resistance and extended wheel life. Our OEM-certified painting facility guarantees automotive-standard double anti-corrosion protection. Shot blasting, zinc-phosphate pre-treatment, and epoxy E-coating maximize corrosion resistance of our products in hard-to-reach areas. With salt spray rust resistance up to 1000 hours, JANTSA wheels set an industry standard for compliance to the strictest customer expectations.

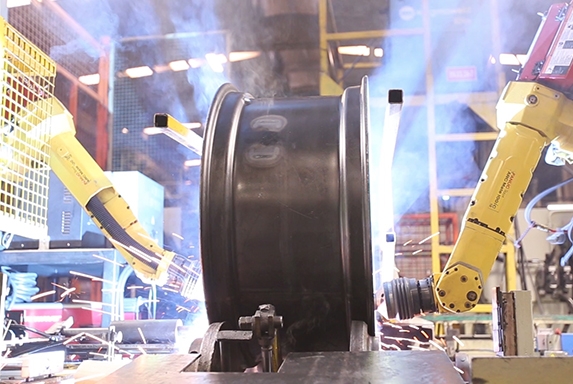

Welding

In many respects, wheel strength is determined by the quality of penetration between its two main components: the disc and the hub. Automated submerged arc and gas metal arc welding eliminates human error and ensures consistency at every stage of the process. Our welding processes are kept under control through weld penetration testing.

Packaging

High-quality wheel packaging is a must, considering typical longevity of international transportation and wheel storage. We prevent potential damage of final products by and various stabilizing elements for wheel palletizing, such as vacuum nylon packaging, plastic clips and separators. All wooden pallets correspond to international fumigation requirements. Moreover, customized packaging and pallet sizes are applied to cater diverse needs of our international customers.

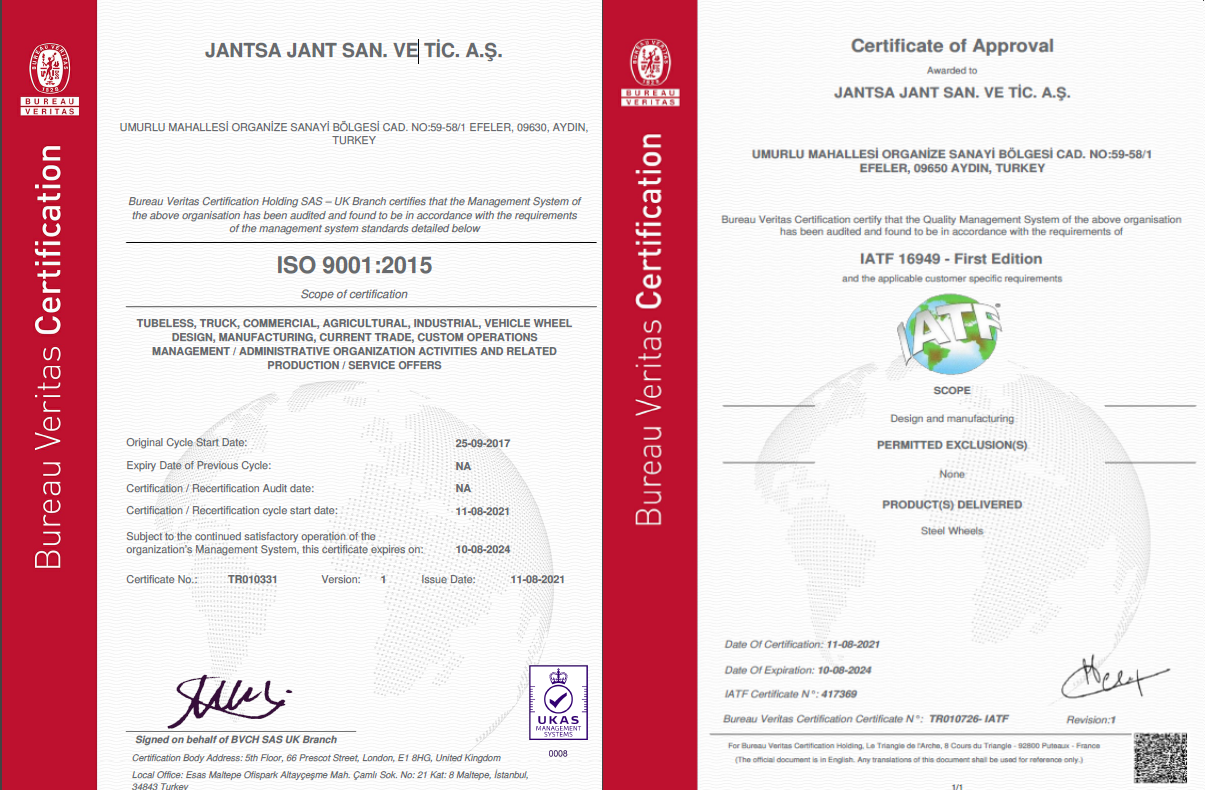

Certificates

JANTSA quality is ensured through the certification of all facilities and the management system. It operates within the framework of continuous improvement with ISO 9001 and IATF 16949 Quality Management Systems, while also protecting environmental resources with ISO 14001. With the ISO 45001, ISO 50001 and ISO 27001 systems, it also meets the requirements for Occupational Health and Safety, Energy Efficiency Management, and Information Security. Finally, to ensure the quality of our custom welding processes, we adhere to national welding standards for our product quality.

Technical Cooperation

Our quality leadership is assured by technical cooperation with renowned universities and scientific institutions, such as:

- LBF (Fraunhofer Institute)

- Dokuz Eylul University

- BV (Bureau Veritas)

- TÜV

- TUBITAK

- TSE (Turkish standards institute)

- DLG (German Agricultural Society).

Standarts

JANTSA products are designed, manufactured, and tested in compliance with a number of international standards, including:

- TSE - Turkish Standards Institution

- ETRTO - European Tire and Rim Technical Organization

- EUWA - Association of European Wheel Manufacturers

- SAE - Society of Automotive Engineers

- JIS - Japanese Industrial Standards

- TRA - The Tire & Rim Association